Electric motors are the workhorses of many industrial and commercial applications, driving machinery and equipment that power production lines, HVAC systems, and more. However, like any piece of mechanical equipment, electric motors can encounter issues that disrupt their operation and, ultimately, affect your productivity. In this article, we’ll explore the top five common causes of electric motor problems, their causes, and practical solutions to fix them. By understanding these issues and how to address them, you can extend the lifespan of your motors and keep your operations running smoothly.

1. Electric Motor Problems: Overheating

Overview:

Overheating is one of the most common problems faced by electric motors. When a motor runs too hot, it can lead to insulation breakdown, reduced efficiency, and even complete motor failure. Overheating can be caused by several factors, including excessive load, poor ventilation, and electrical issues.

Causes of Overheating:

- Overloading: Running a motor beyond its rated capacity can cause it to draw more current, leading to excessive heat generation.

- Poor Ventilation: Inadequate cooling or blocked air passages can prevent heat from dissipating, causing the motor to overheat.

- Electrical Motor Problems: Issues such as low voltage, unbalanced supply voltage, or high ambient temperatures can increase current draw and cause overheating.

Solutions to Overheating with Electric Motor Problems:

- Reduce Load: Ensure the motor is operating within its rated capacity. If the load is too high, consider using a motor with a higher power rating.

- Improve Ventilation: Make sure the motor’s cooling system is functioning correctly. Clean any dust, dirt, or debris blocking air vents and ensure proper airflow around the motor.

- Check Electrical Supply: Verify that the voltage and frequency supplied to the motor match its specifications. Address any issues with voltage imbalance or low voltage that could contribute to overheating.

2. Electric Motor Problems: Bearing Failure

Overview:

Bearings are critical components in electric motors, supporting the rotating shaft and reducing friction between moving parts. Bearing failure is a common cause of motor breakdowns, often resulting in increased noise, vibration, and eventually, motor failure.

Causes of Bearing Failure with Electric Motor Problems:

- Improper Lubrication: Either too much or too little lubrication can lead to bearing wear and failure.

- Contamination: Dust, dirt, and moisture can enter the bearing housing, leading to premature wear.

- Misalignment: Misaligned shafts can cause uneven load distribution on the bearings, leading to excessive wear.

- Overloading: Excessive load on the motor can put additional stress on the bearings, leading to premature failure.

Solutions to Bearing Failure with Electric Motor Problems:

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals and use the correct type of lubricant for your motor’s bearings.

- Keep Bearings Clean: Protect bearings from contamination by ensuring that seals and shields are intact and functioning correctly.

- Check Alignment: Regularly inspect the alignment of the motor shaft and adjust as necessary to ensure even load distribution on the bearings.

- Monitor Load: Ensure the motor is not subjected to excessive load. If the load exceeds the motor’s capacity, consider upgrading to a motor with a higher power rating.

3. Electric Motor Problems: Electrical Insulation Failure

Overview:

Electrical insulation within a motor prevents electrical current from leaking and causing short circuits or ground faults. Insulation failure is a serious issue that can lead to motor burnout and pose a safety hazard.

Causes of Electrical Insulation Failure:

- Overheating: Prolonged exposure to high temperatures can degrade insulation materials.

- Moisture: Water or condensation inside the motor can cause insulation to deteriorate, leading to electrical faults.

- Contamination: Dust, oil, and chemicals can weaken insulation, reducing its effectiveness.

- Aging: Insulation naturally degrades over time, especially in older motors.

Solutions to Electrical Insulation Failure:

- Regular Testing: Perform regular insulation resistance testing (such as Megger testing) to monitor the condition of the motor’s insulation and identify potential issues before they lead to failure.

- Temperature Control: Ensure the motor operates within its specified temperature range to prevent insulation degradation. Address any overheating issues promptly.

- Moisture Control: Protect motors from moisture by ensuring they are properly sealed and by using space heaters in cold environments to prevent condensation.

- Clean Environment: Keep the motor and its surroundings clean to prevent contamination from dust, oil, and other substances.

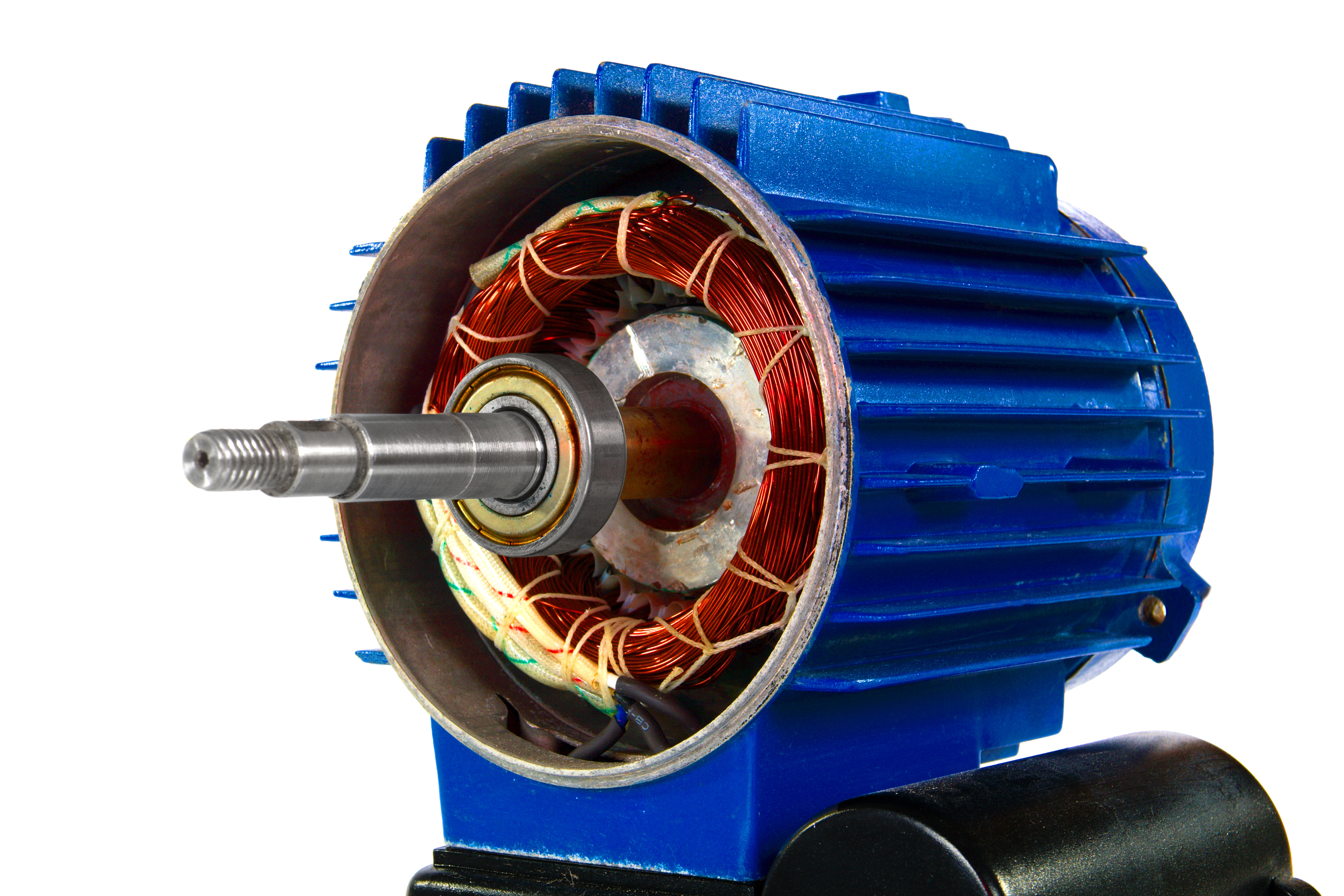

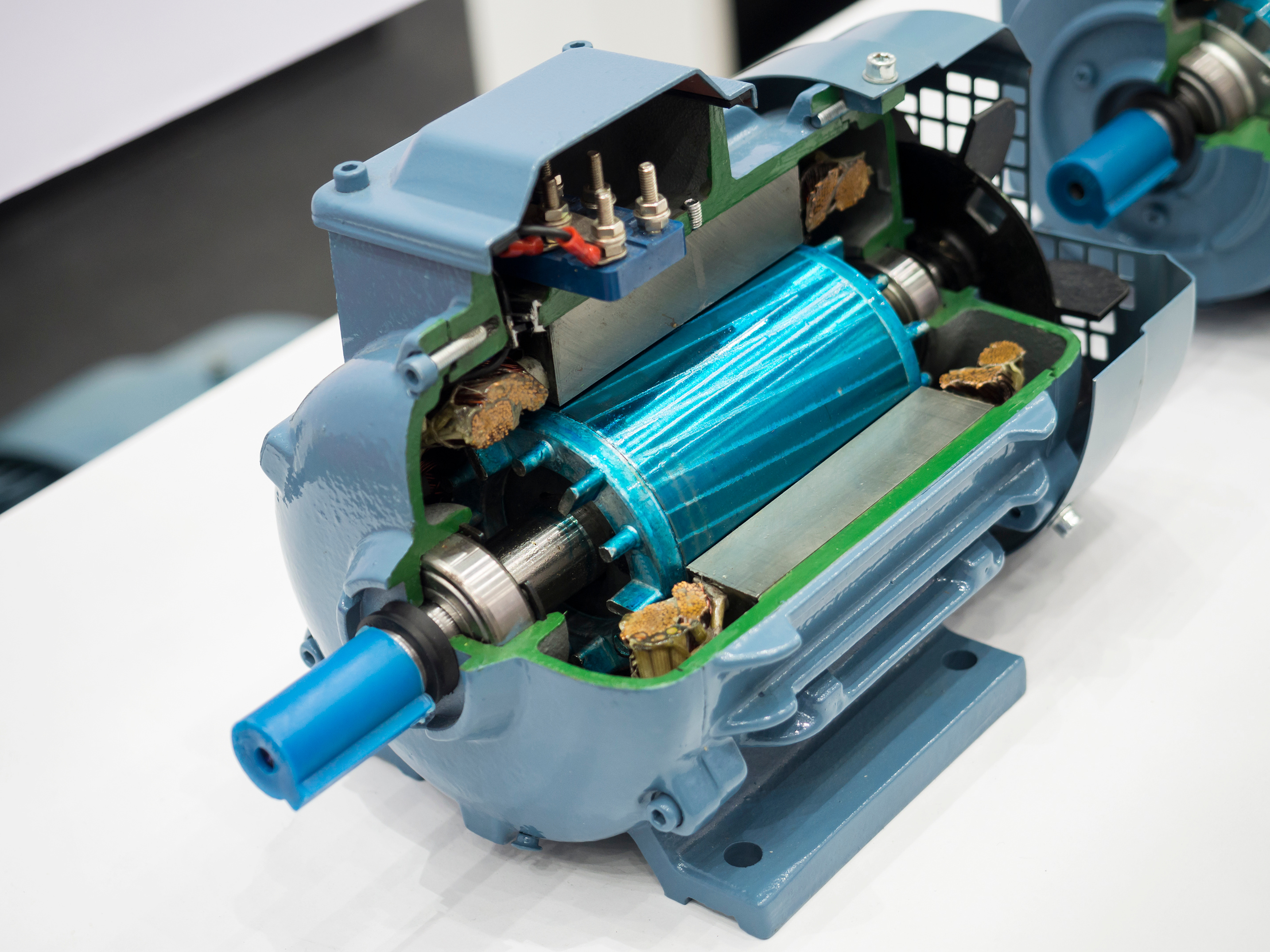

4. Electric Motor Problems: Rotor and Stator Problems

Overview:

The rotor and stator are the main components of an electric motor that work together to generate rotational motion. Issues with either the rotor or stator can lead to reduced motor performance, excessive vibration, and even complete motor failure.

Causes of Rotor and Stator Problems:

- Eccentricity: Misalignment between the rotor and stator can cause uneven air gaps, leading to vibrations and noise.

- Broken or Loose Windings: Damaged windings in the stator or rotor can disrupt the magnetic field, reducing motor efficiency and causing overheating.

- Rotor Bar Damage: In squirrel cage motors, broken rotor bars can lead to uneven torque and reduced motor performance.

Solutions to Rotor and Stator Problems:

- Regular Inspections: Conduct routine inspections to check for signs of wear, damage, or misalignment in the rotor and stator. Look for unusual vibrations or noises that may indicate a problem.

- Rotor Balancing: If the rotor is out of balance, perform dynamic balancing to correct any imbalances and reduce vibration.

- Repair or Replace Windings: If windings are damaged, they may need to be repaired or replaced to restore proper motor function.

- Address Eccentricity: Ensure that the rotor and stator are properly aligned to maintain even air gaps and prevent eccentricity-related issues.

5. Electric Motor Problems: Vibration and Noise Issues

Overview:

Excessive vibration and noise are common symptoms of underlying electric motor problems. These issues can lead to premature wear, reduced efficiency, and even motor failure if not addressed promptly.

Causes of Vibration and Noise:

- Imbalance: An unbalanced rotor can cause excessive vibration, leading to noise and reduced motor life.

- Misalignment: Misaligned motor components, such as the shaft or bearings, can result in uneven load distribution and increased vibration.

- Loose Components: Loose bolts, mounts, or other components can lead to increased noise and vibration during operation.

- Resonance: Operating at certain frequencies can cause resonance, amplifying vibrations and noise.

Solutions to Vibration and Noise Issues of Electric Motor Problems:

- Dynamic Balancing: Perform dynamic balancing on the rotor to correct any imbalances and reduce vibration and noise.

- Check Alignment: Ensure that all motor components are properly aligned to minimize vibration. This includes checking the alignment of the shaft, bearings, and couplings.

- Secure Components: Regularly inspect and tighten any loose components to prevent noise and vibration. Ensure that all mounts and bolts are secure.

- Avoid Resonance Frequencies: Identify and avoid operating the motor at frequencies that cause resonance. Adjusting the speed or frequency can help mitigate this issue.

Preventative Maintenance: The Key to Avoiding Electric Motor Problems

Preventing electric motor problems is always better than fixing them. Implementing a robust preventative maintenance program can help identify and address issues before they lead to motor failure. Here are some best practices for maintaining electric motors:

- Regular Inspections: Schedule routine inspections to check for signs of wear, damage, or misalignment. Look for unusual noises, vibrations, or overheating, which may indicate a problem.

- Scheduled Testing: Conduct regular motor testing, including insulation resistance testing, ground testing, and vibration analysis, to monitor the motor’s health.

- Proper Lubrication: Follow the manufacturer’s guidelines for lubrication intervals and use the correct type of lubricant. Over-lubrication or under-lubrication can both lead to bearing failure.

- Environmental Control: Keep the motor’s operating environment clean and free from contaminants. Ensure adequate ventilation and protect the motor from moisture and extreme temperatures.

- Training: Ensure that your maintenance staff is properly trained in motor maintenance and repair techniques. Regular training can help prevent common mistakes that lead to motor failure.

Conclusion for Electric Motor Problems

Electric motors are essential to the smooth operation of countless industrial and commercial processes. By understanding the common problems that can affect these motors and knowing how to address them, you can reduce downtime, lower maintenance costs, and extend the life of your equipment. Whether it’s overheating, bearing failure, insulation issues, rotor and stator problems, or vibration and noise, taking proactive steps to maintain and repair your motors will pay off in the long run. Implementing a comprehensive preventative maintenance program is the best way to keep your motors running efficiently and avoid unexpected breakdowns.

For professional motor testing, repairs, and modifications, trust A Plus Electric Motor Repair, Inc. Our expert technicians are here to help you keep your operations running smoothly. A Plus Electric Motor Repair, Inc. implements a rigorous and detailed oriented inspection and repair procedure on all electric motor problems for repair. Our trained staff meticulously examines each motor to provide the highest quality repair needed to restore your motor to manufacturer’s specifications.