Table of Contents

A Complete Solution for All Your Machining Shop Needs

At A Plus Electric Motor Repair, Inc., our Machining Shop offers an all-encompassing solution for a wide range of machining needs. Equipped with advanced machinery and operated by highly skilled technicians, we ensure precision and reliability for every project. From crafting custom parts to managing large-scale production, our shop is built to handle diverse requirements with unmatched efficiency. Whether repairing worn-out components or fabricating intricate designs, our team leverages cutting-edge tools to maintain the highest quality standards. This focus on precision allows us to support industries relying on dependable, well-functioning equipment.

Our Machining Shop is dedicated to delivering timely and tailored solutions for businesses of all sizes. We understand that equipment downtime can be costly, which is why we prioritize quick turnarounds without compromising on quality. By offering a wide range of services, including part fabrication, refurbishing, and modifications, we help our clients achieve seamless operation in their day-to-day processes. Backed by years of expertise, our machine shop stands as a trusted partner for industries requiring consistent and accurate machining services. The versatility of our operations ensures that we meet the needs of each unique project while maintaining the reliability that customers expect.

Innovative Design with CAD Technology

Our Machining Shop leverages advanced CAD (Computer-Aided Design) technology to redefine the manufacturing process, delivering precision and efficiency. Skilled engineers craft intricate 3D models and technical blueprints, which serve as detailed guides for producing each component. By simulating parts before fabrication, we proactively identify and address potential design flaws, ensuring smooth functionality and optimal performance. This innovative approach not only minimizes errors but also streamlines production, reducing both time and material waste. The integration of CAD technology guarantees consistent, high-quality results for every project, whether it’s a custom part or a complex assembly. By prioritizing accuracy and efficiency, we ensure that each component meets the highest standards and aligns perfectly with your operational requirements.

The integration of CAD software in our Machining Shop empowers us to handle even the most intricate projects with exceptional accuracy. This advanced technology allows for detailed visualization and refinement of designs, ensuring that custom components and replicated parts meet exact specifications. By addressing potential issues during the design phase, CAD technology eliminates the need for costly revisions during manufacturing, streamlining the entire production process. This innovative approach bridges creativity and precision, enabling us to deliver high-quality components that perform seamlessly within your operations. With the ability to make precise adjustments and modifications before production, we ensure that every piece not only meets but exceeds expectations, aligning perfectly with your operational requirements and industry standards.

Flexibility with No Minimum Quantity Requirements

At A Plus Electric Motor Repair, Inc., our Machining Shop provides unmatched flexibility by accepting orders with no minimum quantity requirements. We recognize that every project is unique, and not all needs call for large-scale production runs. Whether you’re in need of a single replacement part or a small batch of custom components, we are equipped to deliver precise and cost-effective solutions. By eliminating minimum order restrictions, we empower clients to efficiently manage repairs and maintenance, ensuring they get exactly what they need without incurring unnecessary costs or delays.

This approach highlights our dedication to adaptability and customer satisfaction, ensuring every client receives personalized attention. The Machining Shop serves a wide range of industries, from small businesses to large enterprises, delivering consistent quality regardless of project size. This flexibility is especially valuable for clients needing specialized parts or prototypes, as it allows for customized solutions tailored to precise specifications. By accommodating both small and large orders, we enable businesses to maintain operational efficiency and minimize downtime. Whether creating unique components or handling urgent needs, our focus remains on providing reliable, high-quality results that keep equipment running smoothly. This commitment ensures that each project contributes to the success and continuity of our clients’ operations.

Consistency and Accuracy with CNC Machining

CNC (Computer Numerical Control) machining offers a level of precision and consistency that sets it apart in modern manufacturing. Using advanced technology, this process enables the creation of intricate components with exceptionally tight tolerances, ensuring each part is produced to exact specifications. From one-off prototypes to large-scale production runs, CNC machining is ideal for projects requiring a high degree of detail and accuracy. Its ability to handle complex designs with ease makes it a cornerstone for industries demanding reliability and precision.

The Machining Shop leverages CNC technology to ensure that consistency is maintained across all production stages, no matter the scale. Each machine operates with programmed instructions that eliminate the risk of human error, delivering repeatable results for every batch. This makes CNC machining particularly valuable for applications where uniformity is critical, such as in aerospace or medical device manufacturing. By combining cutting-edge machinery with skilled technicians, the Machining Shop consistently delivers high-quality components tailored to meet diverse client needs.

Extending Equipment Lifespan with Custom Part Recreation

For industries facing the challenge of obsolete or hard-to-find components, custom part recreation offers a reliable solution to sustain operations without interruptions. By carefully analyzing existing parts or utilizing detailed blueprints, we reproduce components that precisely match the original specifications. This approach not only minimizes downtime but also eliminates the costly need for full equipment upgrades or replacements. Custom part recreation is particularly valuable for businesses relying on legacy machinery, where sourcing replacement parts can be both time-consuming and expensive. With this service, companies can maintain their production efficiency while preserving the integrity of their equipment, ensuring seamless functionality for years to come.

The Machining Shop excels at breathing new life into older equipment through precise part replication services. By tailoring solutions to meet specific requirements, the shop enables companies to extend the lifespan of essential machinery and reduce operational costs. Reproduced components are crafted to integrate seamlessly with existing systems, supporting smooth and reliable performance. These custom recreations are a lifeline for businesses in industries where downtime is not an option, such as manufacturing and industrial production. By solving supply chain obstacles and maintaining operational efficiency, the Machining Shop empowers businesses to continue thriving, even with aging equipment.

Precision Turning for Smooth Cylindrical Components

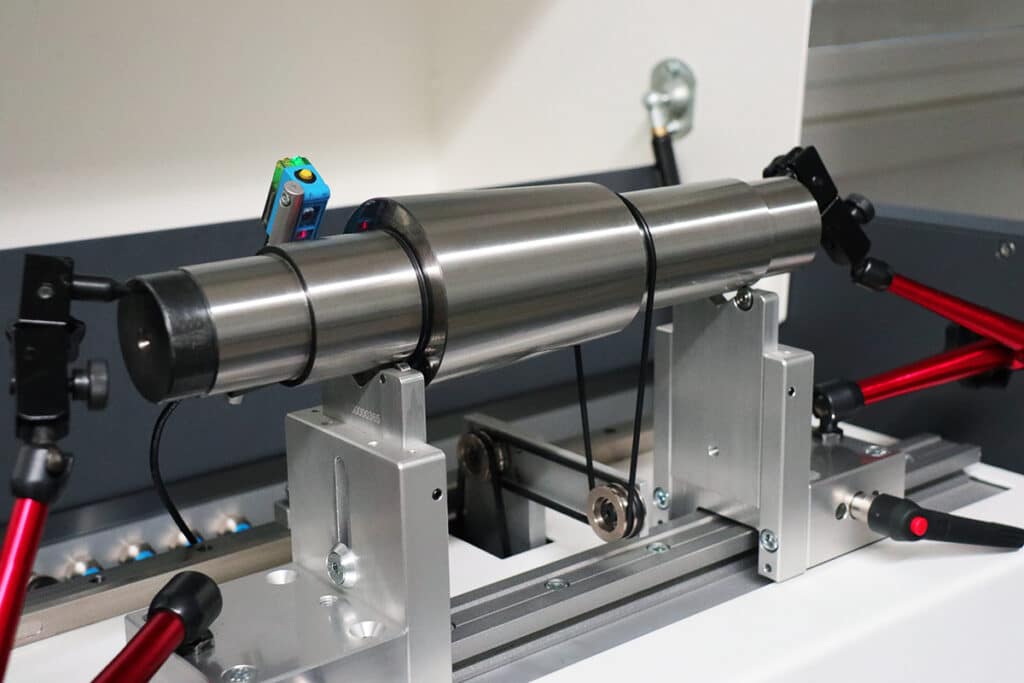

Turning plays a vital role in manufacturing high-quality cylindrical components, offering unmatched accuracy and smooth finishes. Utilizing cutting-edge lathes capable of handling parts up to 22 inches in swing, we create components such as shafts, bushings, and other rotational parts with meticulous detail. This process is integral for industries requiring precision engineering, from automotive to aerospace. With the ability to handle diverse materials, turning provides flexibility in meeting various design specifications while maintaining consistent quality. By achieving the required tolerances and surface finishes, this technique ensures reliable performance and longevity in every component produced.

The Machining Shop excels in precision turning, catering to the specific needs of industries that demand high-performance components. The versatility of the turning process allows for the production of parts using various materials, ensuring compatibility with a wide range of applications. Advanced equipment and skilled machinists work together to deliver products that meet exact specifications, whether for prototypes or high-volume production. From custom bushings to critical shafts, the turning process guarantees both functionality and durability. By integrating precision and efficiency, the Machining Shop supports industries that rely on smooth-operating cylindrical components to keep their operations running seamlessly.

Milling for Complex Geometries and Features

Milling is an essential process in modern manufacturing, offering unmatched versatility for creating complex geometries and intricate features. With advanced milling machines, we handle everything from flat surfaces and slots to detailed 3D contours with precise tolerances. This process is ideal for industries requiring high-performance components, such as automotive, aerospace, and medical. Milling ensures accurate shaping, drilling, and cutting, resulting in parts with exceptional surface finishes and reliability. The ability to work with various materials, including metals and plastics, adds to its flexibility, allowing for tailored solutions to meet specific design requirements. By using this technology, manufacturers achieve both functional and aesthetic excellence in their components.

The Machining Shop specializes in precision milling services, catering to projects that demand intricate designs and tight tolerances. Our milling capabilities extend to producing highly detailed parts for custom prototypes, small batches, and large production runs. Skilled machinists utilize cutting-edge equipment to ensure consistent quality and repeatable results, regardless of the complexity involved. Milling not only shapes components but also enhances their functionality by adding grooves, holes, and other critical features. This process is indispensable for creating high-precision parts that meet the rigorous demands of modern engineering applications, ensuring durability and superior performance in every finished product.

Accurate Finishes with Drilling & Grinding

Precision drilling and grinding are at the heart of modern manufacturing, ensuring components meet exacting standards. Drilling creates precise holes of varying sizes, tailored to fit specific design requirements, whether for assembly, fasteners, or specialized applications. Grinding complements this by refining surfaces, achieving smooth finishes and the highest tolerances essential for critical parts. These processes are indispensable in industries like aerospace, automotive, and medical, where accuracy can directly impact safety and performance. By integrating advanced machinery with skilled expertise, these techniques ensure components not only function optimally but also fit seamlessly within larger systems, setting a new standard for quality.

The Machining Shop delivers precision drilling and grinding solutions for projects that demand polished and accurate finishes. With state-of-the-art equipment and experienced technicians, the shop handles everything from small, intricate parts to large-scale components. Drilling allows for precise placement and alignment, while grinding achieves impeccable smoothness and dimensional accuracy. These services are vital for producing high-performance parts used in various industrial applications, ensuring reliability and longevity. By focusing on quality and attention to detail, the Machining Shop provides tailored solutions that elevate the durability and functionality of every product, meeting the rigorous demands of today’s manufacturing standards.

Durable Welding Solutions with MIG & TIG

Joining metal components requires both expertise and the right welding method to ensure lasting durability. MIG (Metal Inert Gas) welding is an excellent choice for thicker materials, offering speed and efficiency without compromising strength. This method is often used in structural projects and manufacturing industries where robust welds are essential. On the other hand, TIG (Tungsten Inert Gas) welding delivers unparalleled precision, making it ideal for thinner materials and intricate designs, such as in aerospace or automotive applications. With skilled welders and advanced techniques, projects are completed to the highest standards, ensuring the welds are both clean and reliable.

The Machining Shop integrates MIG and TIG welding services to meet the diverse needs of its clients. Whether handling heavy-duty industrial work or delicate repairs, the team adapts its methods to suit each project’s unique requirements. MIG welding provides the necessary strength for load-bearing applications, while TIG welding is favored for its precision and ability to handle complex details. Every weld is crafted to ensure durability, offering solutions that withstand both time and pressure. By maintaining a commitment to quality and versatility, the Machining Shop delivers welding solutions that exceed expectations across various industries.

Tailored Solutions for Specialized Needs

Standard components often fall short when dealing with unique challenges or specialized equipment. That’s where custom engineering steps in, offering a solution designed specifically for your application. By combining advanced CAD (Computer-Aided Design) technology with precise CNC machining capabilities, engineers can craft parts that not only meet but exceed functional requirements. Whether it’s improving performance, adapting to uncommon specifications, or innovating entirely new designs, the focus is on creating solutions that are as effective as they are efficient. Each project is approached with creativity and technical skill, ensuring the results align perfectly with the client’s operational needs.

The Machining Shop plays a vital role in delivering these custom-engineered components, transforming concepts into tangible results. From initial consultation to final production, the process emphasizes collaboration and quality. Engineers work closely with clients to understand their specific challenges, translating those insights into detailed designs that maximize functionality and durability. Advanced CNC machining tools then bring these designs to life with unmatched precision, ensuring each part integrates seamlessly with the intended equipment. This tailored approach not only addresses immediate challenges but also improves overall system efficiency, making the Machining Shop an essential partner in achieving long-term success.

Extending Value Through Preventive Maintenance

Preventive maintenance is essential for maximizing the performance and longevity of your equipment. Routine inspections, precise recalibrations, and timely adjustments help identify and address potential issues before they lead to costly failures. By ensuring that components are consistently in optimal condition, businesses can minimize downtime, avoid emergency repairs, and enhance overall productivity. These measures are particularly valuable for operations that rely on complex or high-demand machinery, where even minor disruptions can lead to significant delays. Preventive care not only preserves the value of your investment but also promotes safety and reliability, making it a smart strategy for long-term success.

The Machining Shop integrates preventive maintenance into its comprehensive range of services, emphasizing the importance of proactive solutions. Through detailed evaluations and expert recommendations, the team works closely with clients to develop customized maintenance schedules tailored to their equipment’s specific needs. Whether it’s recalibrating critical components or fine-tuning operational systems, these efforts ensure that machinery performs efficiently and consistently. Preventive maintenance also helps extend the usable life of parts, reducing the need for frequent replacements and saving resources over time. With the Machining Shop’s expertise, businesses gain peace of mind knowing their equipment is cared for by skilled professionals dedicated to precision and reliability.

Partner with A Plus Electric Motor Repair

Preventive maintenance is essential for maximizing the performance and longevity of your equipment. Routine inspections, precise recalibrations, and timely adjustments help identify and address potential issues before they lead to costly failures. By ensuring that components are consistently in optimal condition, businesses can minimize downtime, avoid emergency repairs, and enhance overall productivity. These measures are particularly valuable for operations that rely on complex or high-demand machinery, where even minor disruptions can lead to significant delays. Preventive care not only preserves the value of your investment but also promotes safety and reliability, making it a smart strategy for long-term success.

The Machining Shop integrates preventive maintenance into its comprehensive range of services, emphasizing the importance of proactive solutions. Through detailed evaluations and expert recommendations, the team works closely with clients to develop customized maintenance schedules tailored to their equipment’s specific needs. Whether it’s recalibrating critical components or fine-tuning operational systems, these efforts ensure that machinery performs efficiently and consistently. Preventive maintenance also helps extend the usable life of parts, reducing the need for frequent replacements and saving resources over time. With the Machining Shop’s expertise, businesses gain peace of mind knowing their equipment is cared for by skilled professionals dedicated to precision and reliability.