Table of Contents

The Importance of Motor Testing

Motor testing is a crucial process in evaluating the performance, efficiency, and reliability of electric motors. Whether used in industrial machinery, HVAC systems, or manufacturing equipment, motors undergo stress and wear over time. Regular testing helps detect potential failures before they cause costly downtime. By analyzing factors such as insulation integrity, electrical balance, and operational efficiency, motor testing ensures that equipment remains in peak working condition. Proper testing also extends the lifespan of motors and reduces maintenance costs.

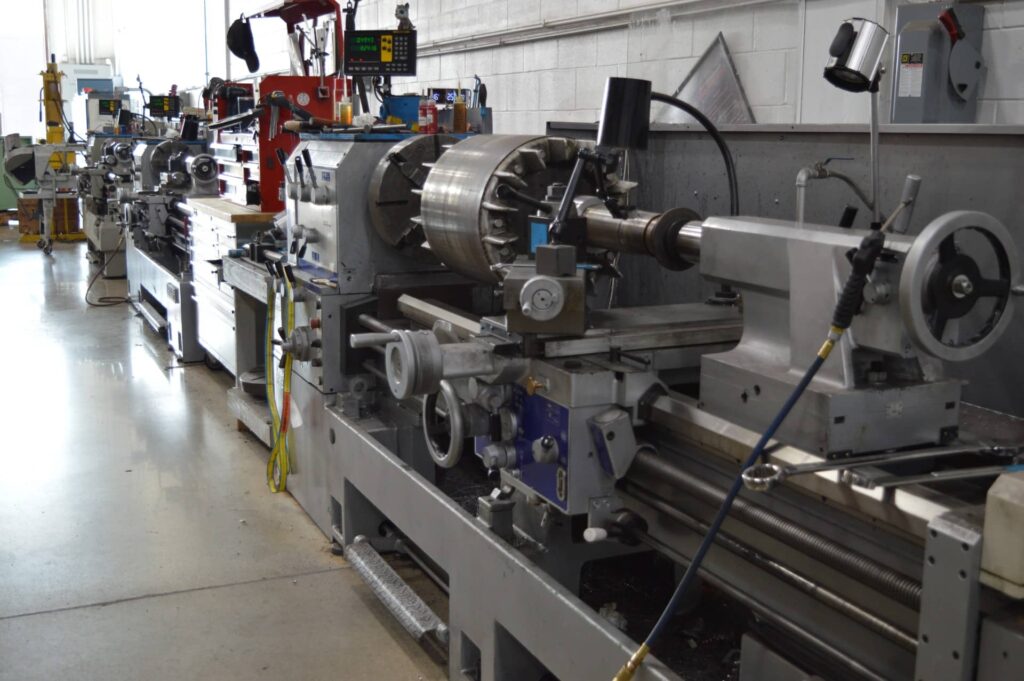

Advanced Equipment for Accurate Diagnostics

Modern motor testing relies on sophisticated diagnostic equipment designed to evaluate various electrical and mechanical parameters. Tools such as digital multimeters, surge testers, and core loss testers help technicians assess motor performance with high precision. Infrared thermal imaging detects overheating issues, while oscilloscopes analyze waveform distortions. These advanced tools provide comprehensive insights, allowing for precise troubleshooting and effective repairs. High-tech testing equipment enhances accuracy and ensures motors meet strict industry standards.

Insulation Resistance Testing

Insulation plays a crucial role in maintaining the efficiency and longevity of electric motors by preventing electrical leakage and short circuits. Over time, factors such as heat exposure, moisture ingress, and mechanical wear can degrade insulation, compromising the motor’s ability to function safely. Insulation resistance testing is a preventive measure that helps identify weakened insulation before it leads to failure. Technicians use megohmmeters to apply a controlled voltage and measure how well the insulation resists electrical flow. If resistance readings are too low, it indicates deterioration, increasing the risk of electrical shorts. Through motor testing, industries can assess insulation health and take corrective actions to prevent costly failures, improving motor reliability in high-demand applications like manufacturing and automation.

Routine insulation resistance testing is essential for motors operating in harsh environments where exposure to contaminants, humidity, and voltage fluctuations is common. Low resistance readings may indicate contamination buildup or aging insulation, both of which can lead to overheating and eventual breakdown. By conducting motor testing, technicians can determine whether insulation needs maintenance or replacement to maintain safe operation. This test is particularly valuable for motors used in industrial plants, HVAC systems, and power generation, where uninterrupted performance is critical. Implementing a scheduled testing program allows businesses to extend motor lifespan, reduce energy waste, and avoid unplanned downtime caused by electrical insulation failures.

Surge Comparison Testing

Surge comparison testing evaluates the integrity of motor windings and identifies potential faults before they become serious issues. This test applies a high-voltage surge to the windings, comparing responses between each phase. If an irregularity is detected, it may indicate weak or damaged insulation. Surge testing is an essential step in diagnosing electrical imbalances, reducing the risk of short circuits, and ensuring reliable motor operation.

Core Loss Testing for Efficiency Analysis

Core loss testing is a method used to evaluate the efficiency of an electric motor’s core. When a motor operates, energy is lost due to hysteresis and eddy currents within the core. Excessive core loss can lead to overheating, decreased efficiency, and increased energy consumption. By using specialized core loss testers, technicians can determine if the motor’s core needs repair or replacement. This test ensures that the motor operates at optimal energy efficiency, reducing power consumption and operating costs.

Dynamic Balancing for Smooth Operation

Excessive vibration in electric motors can significantly impact their performance, leading to premature wear on critical components such as bearings, shafts, and housing. This issue often stems from imbalances in the rotating assembly, which create unnecessary strain on the motor. To address this, technicians perform motor testing using high-precision balancing machines to identify weight distribution issues. These machines detect even the slightest irregularities, allowing technicians to make precise corrections. By strategically adjusting weights or modifying components, dynamic balancing restores equilibrium to the motor, ensuring smoother operation. Industries that rely on high-speed machinery, such as aerospace, automotive, and manufacturing, benefit greatly from dynamic balancing, as it helps reduce stress on mechanical parts, improves efficiency, and extends operational lifespan.

Dynamic balancing is particularly essential for motors operating at high RPMs, where even a minor imbalance can escalate into significant mechanical failure. Unchecked vibrations can loosen mounting bolts, degrade insulation, and cause alignment issues, leading to costly repairs or complete motor failure. Through motor testing, technicians evaluate vibration patterns and determine the necessary corrections to restore stability. Properly balanced motors not only experience reduced wear but also operate more efficiently, consuming less energy and producing minimal noise. Regular dynamic balancing as part of preventive maintenance can prevent unexpected breakdowns, ensuring uninterrupted productivity in industrial applications. By investing in precision balancing, businesses can maintain consistent performance, reduce maintenance costs, and extend the useful life of their electric motors.

Vibration Analysis for Early Detection

Vibration analysis is a crucial diagnostic tool for detecting mechanical issues in electric motors. Excessive vibration may indicate problems such as misalignment, bearing wear, or unbalanced rotor components. Using vibration analyzers, technicians measure frequency patterns and identify irregularities before they cause severe damage. Addressing vibration-related issues early prevents costly repairs and ensures consistent motor performance.

Evaluating Motor Performance Under Load

Electric motors must operate under varying conditions, and their ability to handle stress determines their efficiency and reliability. Load testing plays a crucial role in assessing how well a motor performs when subjected to real-world operational demands. By applying a controlled load, technicians can evaluate critical factors such as torque, speed, and power efficiency. This process helps identify potential weaknesses that could lead to failure under normal working conditions. Through motor testing, technicians can determine whether a motor meets required specifications before installation. Industries such as manufacturing, transportation, and HVAC systems depend on motors functioning at peak efficiency, making load testing essential for maintaining operational stability and preventing costly breakdowns.

Beyond performance verification, load testing is vital for diagnosing potential issues that could compromise motor function over time. Motors that struggle under load may exhibit signs of overheating, voltage irregularities, or mechanical inefficiencies, all of which can lead to premature failure. By conducting motor testing, technicians can pinpoint faults, such as weak windings, imbalanced rotors, or misaligned components, before they cause severe damage. This proactive approach helps businesses minimize downtime and optimize equipment longevity. Additionally, load testing is valuable when integrating new motors into an existing system, ensuring they align with power requirements and workload expectations. Through thorough evaluation, industries can achieve reliable motor operation and improved energy efficiency.

Ensuring Insulation Integrity and Electrical Safety

Electric motors operate under constant electrical stress, making insulation strength a critical factor in their long-term reliability. High-voltage testing, also known as dielectric withstand testing, is used to evaluate whether motor insulation can endure high electrical loads without failing. During this process, technicians apply a controlled high-voltage current to detect any weak points or potential breakdowns in insulation materials. If the insulation is compromised, the motor becomes susceptible to short circuits and electrical failures, which can result in costly downtime or hazardous conditions. Through motor testing, industries can proactively prevent insulation failures, ensuring motors function safely under operational loads. This is particularly important in high-power applications where motors are exposed to continuous voltage fluctuations.

Detecting insulation weakness early helps prevent catastrophic failures that could lead to equipment damage, fire risks, or safety hazards for personnel. High-voltage testing is a crucial step in quality control for newly manufactured motors and is equally important for routine maintenance of existing equipment. By performing motor testing, technicians can identify insulation deterioration caused by environmental factors such as moisture, contaminants, or prolonged electrical stress. Industries that rely on motors for essential operations, such as power generation, manufacturing, and transportation, benefit from this testing method by ensuring compliance with electrical safety standards. Regular high-voltage testing enhances overall system reliability and extends motor lifespan by preventing unexpected failures.

Thermal Imaging for Heat Detection

Excessive heat can indicate electrical faults, overload conditions, or poor ventilation within a motor. Thermal imaging cameras capture heat signatures, allowing technicians to pinpoint overheating areas without disassembling the motor. By addressing thermal issues early, technicians can prevent damage to windings, bearings, and insulation. Thermal imaging is a non-invasive and efficient method for detecting hidden motor problems.

The Role of Predictive Maintenance

Predictive maintenance relies on regular motor testing to identify issues before they result in failure. By analyzing motor performance trends over time, technicians can schedule maintenance proactively, reducing the likelihood of unexpected breakdowns. Predictive maintenance strategies help businesses optimize uptime, lower repair costs, and extend the operational life of their motors. Incorporating advanced motor testing techniques into a predictive maintenance plan ensures continued efficiency and reliability.

A Plus Electric Motor Repair: Your Motor Testing Experts

At A Plus Electric Motor Repair, we utilize cutting-edge motor testing equipment to diagnose, repair, and optimize electric motors for peak performance. Our technicians perform comprehensive testing, including insulation resistance checks, surge comparison, core loss analysis, and dynamic balancing. By identifying potential issues early, we help businesses avoid costly downtime and extend the lifespan of their motors. Whether you need routine diagnostics or advanced troubleshooting, our expertise ensures that your motors operate at maximum efficiency. Trust A Plus Electric Motor Repair for reliable, professional motor testing services.