Table of Contents

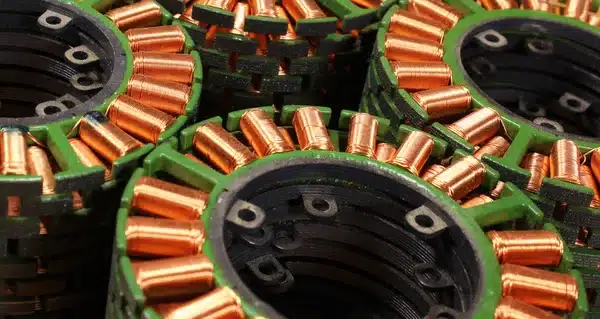

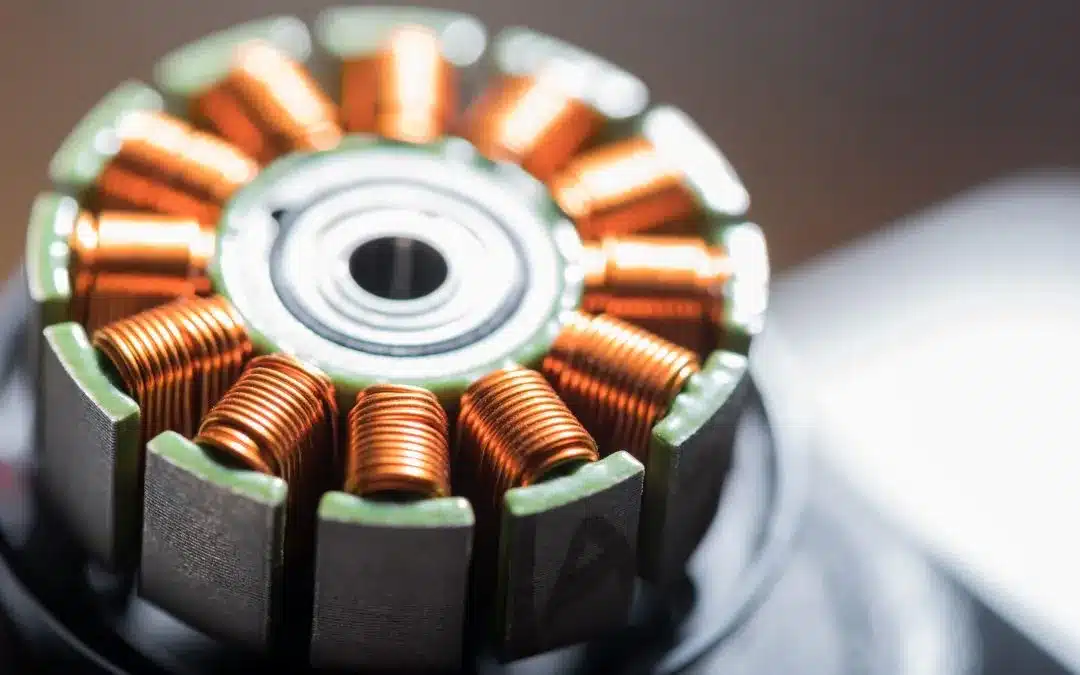

The Power of Copper: The Heartbeat of Electric Motors

Copper wire is more than just a component in electric motors; it’s the lifeblood that powers their very operation. This highly conductive metal is essential for creating the electromagnetic fields that set motor components in motion. The amount of copper wire inside a motor directly correlates with its horsepower (HP), design intricacies, and the demands of its application. From small 3 HP motors to industrial giants with 650 HP, the copper content varies significantly, playing a key role in determining a motor’s efficiency, durability, and overall performance. Without this vital material, electric motors would struggle to deliver the power and reliability needed for modern industrial applications.

Copper Content: A Motor’s Secret to Efficiency and Performance

The amount of bare copper wire wound inside an electric motor isn’t just about size—it’s a reflection of the motor’s efficiency and power capabilities. Higher horsepower motors, often used in demanding industrial environments, require more copper to manage greater electrical loads, ensuring smooth operation and minimizing energy loss. This precious metal’s presence in the motor’s windings is what allows it to generate strong, consistent electromagnetic fields, which are crucial for reliable performance. By understanding the relationship between copper content and motor efficiency, industries can make informed decisions that enhance both their productivity and their energy consumption, all while keeping operations running smoothly.

3 HP Motors: Small but Essential

Small But Mighty: The Copper Wire Content in 3 HP Motors

In the world of electric motors, even the smallest players pack a punch when it comes to copper content. Motors at the lower end of the horsepower spectrum, like 3 HP motors, typically contain between 3 to 5 pounds of copper wire. This copper is crucial for creating the magnetic fields needed to drive motor operation, particularly in the windings around the stator and rotor. While these motors are often used in smaller industrial applications or machinery requiring moderate power, the role of copper remains vital. Despite its modest quantity, the copper in a 3 HP motor ensures efficient electricity conduction, minimizing energy loss and maximizing the motor’s overall performance.

The Critical Role of Copper and Copper Wire in 3 HP Motors

The amount of copper and copper wire in a 3 HP motor might seem small, but it plays an outsized role in the motor’s effectiveness. Copper is a key material in the motor’s windings, where it generates the magnetic field necessary for operation. Even in lower horsepower motors, this copper ensures that the motor runs smoothly, providing reliable power for small industrial tasks and moderate machinery. The efficient conduction of electricity, thanks to the copper windings, helps reduce energy loss and keeps the motor operating at optimal levels. In short, the copper content in these smaller motors is essential for delivering the consistent performance that industries rely on.

10 HP Motors: Moderate Power, Increased Copper

Stepping Up: The Role of Conductive Materials in 10 HP Motors

As we step up to 10 HP motors, the quantity of conductive materials used increases substantially, typically falling within the 8 to 15-pound range. These more robust motors are designed for demanding industrial tasks, such as driving larger pumps, compressors, and conveyor systems. The additional conductive material in these motors enhances their ability to carry higher currents and effectively dissipate heat, both of which are crucial for maintaining efficiency and prolonging the motor’s lifespan. Each strand is meticulously arranged to optimize electromagnetic efficiency, allowing these motors to handle greater power demands without succumbing to overheating.

Meeting Demands: Enhanced Material Use in 10 HP Motors

In 10 HP motors, the need for increased copper materials becomes evident, as these components are integral to their operation in more challenging industrial environments. Whether powering larger machinery or driving essential systems like pumps and compressors, these motors rely on a greater volume of high-quality conductors to handle the elevated electrical loads. This increase not only boosts the motor’s capacity to carry current but also improves heat management, which is vital for avoiding performance issues. The winding process is carefully executed to ensure that these motors can efficiently manage higher power levels, delivering reliable and consistent performance without the risk of overheating.

50 HP Motors: Substantial Copper and Copper Wire for High Demand

Copper Power: The Backbone of 50 HP Motors

When it comes to 50 HP motors, the sheer amount of copper wire involved is impressive, typically ranging from 50 to 100 pounds. This isn’t just about bulk; it’s about building a motor that can thrive in heavy industrial settings where consistent, reliable power is non-negotiable. These motors are designed to handle high electrical currents and operate under continuous load conditions, making the role of copper essential. The wire’s ability to conduct electricity efficiently ensures that the motor can perform at its best without overheating or losing efficiency, even during prolonged use. In industries where downtime is costly, the copper content in these motors is what keeps everything running smoothly.

High-Quality Copper: The Key to Optimal Motor Performance

Not all copper is created equal, and in 50 HP motors, the quality and thickness of the copper wire are just as important as the quantity. High-purity copper wire is the gold standard for these motors, offering superior conductivity that directly impacts the motor’s overall performance. Thicker, high-quality copper wire can carry more current and dissipate heat more effectively, reducing the risk of energy loss and ensuring the motor operates efficiently. This focus on quality means that 50 HP motors are not only powerful but also durable, capable of handling the intense demands of heavy machinery without compromising on performance. In essence, the copper inside these motors is what makes them both powerful and reliable workhorses in industrial applications

100 HP Motors: Industrial Workhorses with Significant Copper

The Heavyweights: Copper’s Role in 100 HP Motors

100 HP motors are the true heavyweights of the industrial world, often packed with 100 to 150 pounds of copper wire. This substantial amount of copper isn’t just for show; it’s essential for these motors to manage the high electrical loads they’re tasked with. Whether driving large-scale manufacturing equipment, powering heavy-duty pumps, or keeping industrial fans running smoothly, these motors rely on copper to maintain their strength and reliability. The extensive copper wire windings play a crucial role in optimizing the electromagnetic field, ensuring the motor can deliver the consistent torque and power required for demanding applications while keeping energy loss and heat generation to a minimum.

Copper Windings: The Heart of 100 HP Motor Efficiency

In 100 HP motors, the copper wire windings are meticulously designed to do more than just conduct electricity—they are key to the motor’s efficiency and performance. The thick, high-quality copper wire used in these motors ensures that the electromagnetic field is optimized for peak operation. This allows the motor to deliver the substantial power needed for industrial tasks while minimizing energy loss and reducing heat buildup. By effectively managing these high electrical loads, the copper windings help maintain consistent torque and power output, making these motors indispensable in environments where reliability and efficiency are critical. The result is a motor that’s not only powerful but also built to withstand the rigors of continuous industrial use.

200 HP Motors: Heavy-Duty Power with High Copper Content

The Power Behind 200 HP Motors: A Copper-Rich Design

In the realm of 200 HP motors, the stakes are high, and so is the copper wire content—ranging from 150 to 250 pounds. These motors are built for heavy-duty applications where immense power is not just a luxury but a necessity. Whether it’s powering mining equipment, large industrial compressors, or advanced manufacturing machinery, these motors rely on their substantial copper windings to manage the intense electrical currents they must handle. The ample copper content is crucial in maintaining the motor’s ability to deliver consistent power, ensuring that even under extreme conditions, these motors perform with the reliability and strength that heavy industries demand.

Engineering Efficiency: The Role of Copper in 200 HP Motors

Copper wire isn’t just abundant in 200 HP motors; it’s strategically integrated to optimize performance. The copper windings in these motors are meticulously engineered to maximize efficiency, which is critical when dealing with high-power demands. By effectively managing electrical currents, these windings help to reduce the risk of overheating—a common challenge in motors of this size. This careful design not only enhances the motor’s operational efficiency but also extends its lifespan, making it a reliable workhorse in environments where continuous, powerful operation is required. The result is a motor that’s as robust as it is efficient, thanks in large part to the expertly utilized copper at its core.

300 HP Motors: Large-Scale Operations with Extensive Copper

Powering the Heavyweights: Copper in 300 HP Motors

In the world of 300 HP motors, the sheer quantity of copper wire is impressive, with each motor containing between 250 to 350 pounds. These motors are not just powerful; they are indispensable in some of the most demanding industrial applications, including oil and gas extraction, power generation, and large-scale manufacturing. The extensive use of copper ensures that these motors can handle the significant electrical currents required for such heavy-duty tasks. The copper windings are crucial for maintaining high efficiency, even under continuous operation and heavy loads, making these motors reliable powerhouses in environments where performance can never falter.

Copper Windings: The Lifeblood of 300 HP Motor Performance

The copper windings in 300 HP motors are meticulously engineered to maximize electrical conductivity and heat dissipation, two critical factors that directly impact motor performance and longevity. In industries where downtime is not an option, these windings play a vital role in ensuring that motors operate smoothly and reliably, even under the strain of continuous, heavy use. The ability of these motors to maintain high efficiency despite their demanding workloads is a testament to the importance of copper in their design. By optimizing the electromagnetic field and reducing heat buildup, these copper windings help keep 300 HP motors at the top of their game, delivering consistent power where it’s needed most.

500 HP Motors: High Performance with Maximum Copper

Powerhouses of Industry: Copper in 500 HP Motors

Motors in the 500 HP range are true powerhouses, often containing an impressive 400 to 500 pounds of copper wire. These motors are essential in large-scale industrial operations, such as steel mills, heavy machinery, and massive pumping systems, where immense power is a basic requirement. The substantial amount of copper wire is critical for managing the enormous electrical currents these motors must handle daily. This copper wire is not just abundant; it’s strategically utilized to ensure that these motors operate with maximum efficiency. By effectively conducting electricity and dissipating heat, the copper windings enable these motors to deliver reliable power with minimal energy loss, making them indispensable in demanding industrial environments.

The Role of Copper: Ensuring Durability and Performance in 500 HP Motors

In 500 HP motors, the quality and quantity of copper wire are key to their durability and high performance. The copper windings are meticulously optimized to reduce energy loss and prevent heat buildup, both of which are crucial for maintaining the motor’s efficiency and longevity. These motors are built to withstand the rigors of continuous, heavy-duty operation, and the copper plays a vital role in this. By providing a stable electromagnetic field and ensuring effective heat management, the copper wire helps these motors operate smoothly under the most challenging conditions. The result is a motor that not only meets but exceeds the demands of large-scale industrial operations, thanks to the critical role of copper in its design.

650 HP Motors: The Pinnacle of Industrial Power

Giants of Industry: The Role of Copper in 650 HP Motors

At the pinnacle of industrial power, 650 HP motors are designed to meet the most demanding applications, often containing an astounding 600 to 700 pounds of copper wire. These motors are vital in sectors like energy production, large-scale manufacturing, and heavy-duty material handling, where top-tier performance and unwavering reliability are non-negotiable. The immense amount of copper within these motors is essential for managing the extreme electrical loads they must endure. This copper is not just a conductor; it’s the backbone that ensures these motors can operate at peak efficiency, handling continuous, high-power demands without faltering.

Precision and Power: Copper’s Role in 650 HP Motor Efficiency

In 650 HP motors, copper wire windings are precisely engineered to maximize efficiency and performance. The substantial copper content allows these motors to create and sustain an optimal electromagnetic field, which is crucial for delivering the powerful, consistent output required in the most challenging industrial environments. These motors are built to minimize energy loss and prevent heat buildup, critical factors in ensuring long-term reliability and operational success. The careful design and substantial copper use in these motors mean they can reliably deliver the immense power needed for demanding tasks, all while maintaining the high efficiency that industrial applications require.

Factors Influencing Copper Content in Motors

Factors Shaping Copper Usage in Industrial Motors

The amount of copper wire in industrial electric motors is influenced by several key factors, including motor design, efficiency standards, and the specific requirements of the application. Motors that are engineered for higher efficiency typically incorporate more copper in their windings. This increase in copper helps to reduce electrical resistance, which in turn improves overall efficiency and minimizes energy loss. The design choices made to optimize performance often hinge on the strategic use of copper, ensuring that the motor can meet the stringent demands of modern industrial operations.

Tailoring Copper Content to Meet Demanding Applications

In environments where motors are subjected to high operational demands, the need for more copper becomes critical. Motors used in such settings often require additional copper to manage increased electrical loads and maintain consistent, reliable performance. The extra copper allows these motors to handle the heavy-duty tasks they’re designed for, ensuring that they can operate efficiently without overheating or suffering from performance degradation. By tailoring the copper content to the specific needs of the application, manufacturers can create motors that not only meet but exceed the expectations for durability, efficiency, and long-term reliability in challenging industrial environments

Conclusion

The Indispensable Role of Copper in Industrial Motors

Copper is a fundamental material in the construction of industrial electric motors, playing a crucial role in determining their efficiency, reliability, and overall performance. Whether it’s a small 3 HP motor or a massive 650 HP giant, the amount of copper wire used varies significantly, reflecting the motor’s specific power requirements and the demands of its intended application. The strategic use of copper in motor windings directly influences how well a motor can handle electrical loads, dissipate heat, and maintain operational efficiency, making it an irreplaceable component in industrial motor design.

Making Informed Decisions with Copper’s Impact in Mind

Understanding the critical role that copper plays in electric motors allows industries to make more informed decisions about motor selection, maintenance, and even recycling. By recognizing how copper contributes to a motor’s performance, companies can choose motors that best meet their operational needs while optimizing energy consumption and reducing costs. Additionally, the knowledge of copper’s value in motors aids in making smarter choices regarding equipment lifecycle management, ensuring that industries get the most out of their investments while minimizing their environmental footprint. Copper’s impact on motor efficiency and durability makes it a key factor in the sustainability and effectiveness of industrial operations.