Cost Comparison: Repairing vs. Replacing Electric Motors

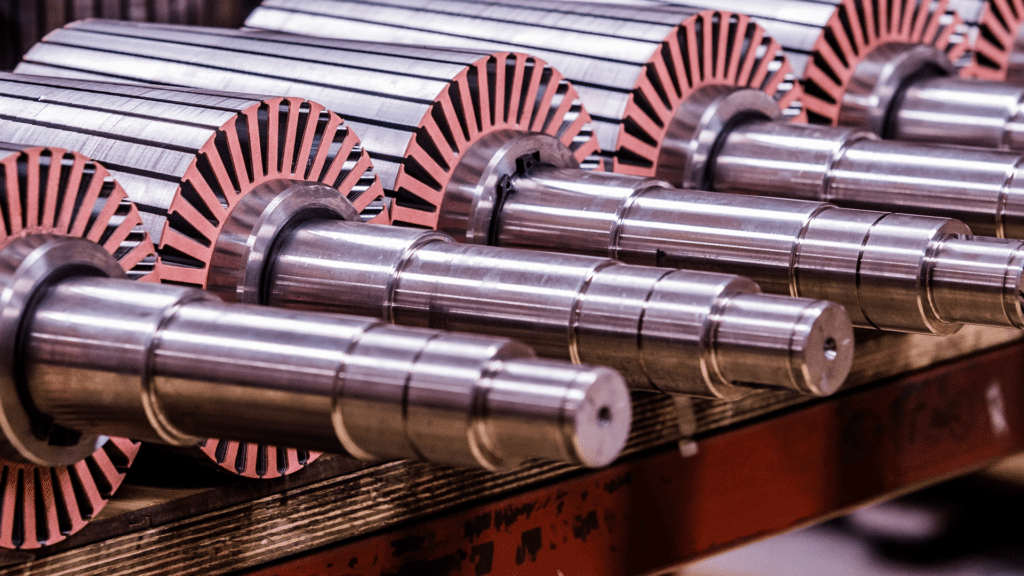

In the industrial and commercial sectors, a cost comparison between repairing and replacing electric motors can be crucial for operational efficiency and budget management. Electric motors power essential machinery, including HVAC systems, conveyor belts, and pumps, all of which are critical to daily operations. As these motors experience wear and tear over time, companies must decide whether repairing the motor or replacing it with a new one is the most economical option. By understanding the factors that influence both repair and replacement costs, companies can make decisions that align with their budget and long-term operational goals.

When deciding between repair and replacement, businesses should consider several elements, including downtime, initial costs, long-term savings, and operational demands. Repairing an existing motor often has a lower initial cost, but may result in additional maintenance down the line, while replacing it can introduce higher upfront costs with potential long-term savings through improved efficiency and durability. Additionally, companies should evaluate the potential for energy savings, as newer motors are often more energy-efficient, offering reduced operating costs over time. By conducting a thorough cost analysis, businesses can determine the option that will best support sustained productivity and meet their financial and operational priorities.

Cost Comparison: Initial Cost Considerations for Repair vs. Replacement of Electric Motors

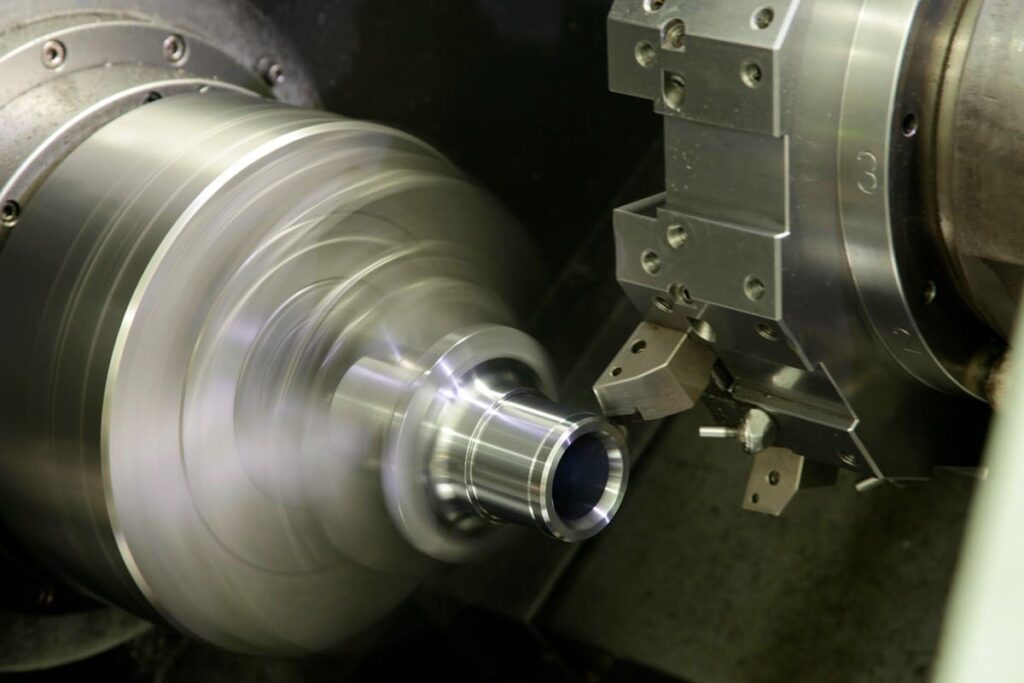

One of the primary factors in deciding between repairing or replacing an electric motor is the initial cost. Generally, repairing a motor is less expensive upfront, with repair costs covering labor, parts, and any necessary diagnostic testing. The overall expense of a repair can vary based on the motor’s size, complexity, and extent of the damage. For businesses looking to manage expenses, repairs often present a lower-cost solution, making it an appealing choice for addressing issues without a significant financial commitment.

On the other hand, replacing an electric motor requires a larger initial investment, particularly if a high-performance or custom model is needed. New motors can be costly, and businesses with budget restrictions may find it challenging to allocate funds for a complete replacement. However, while the initial outlay for replacement is greater, the cost comparison must also consider potential long-term benefits. For example, new motors typically come with warranties, increased efficiency, and potentially lower maintenance requirements. This can make replacement a strategic investment in the right scenarios, but for immediate cost savings, repairs may be more feasible.

Cost Comparison of Downtime: Repair vs. Replacement for Electric Motors

The cost comparison between repair and replacement must account for the cost of downtime, an essential yet often underestimated factor in this decision. Unexpected motor failure can disrupt operations, halt production, and lead to significant financial losses. Repairing a motor can range from a few hours to several days, depending on the severity of the issue and the availability of replacement parts, meaning extended downtime for essential equipment. Downtime costs add up quickly, impacting productivity and overall profitability, making it critical to evaluate repair timelines within the cost comparison to ensure an informed decision-making process.

Replacing a motor can sometimes minimize downtime, particularly if a spare motor is readily available or if the replacement process is straightforward. In such cases, businesses can quickly resume operations, reducing potential financial losses. However, if a replacement motor needs to be ordered or customized, the lead time may be even longer than a repair, delaying the restart of operations and increasing downtime costs. Understanding the potential downtime associated with each option is vital for a complete cost analysis, as it directly affects overall expenses and operational efficiency.

Cost Comparison: Long-term Implications of Repairing vs. Replacing Electric Motors

In a cost comparison, though repairing an electric motor often incurs lower upfront costs, replacement may offer greater financial benefits over time. A new motor, particularly an upgraded model, usually provides enhanced efficiency, reduced maintenance needs, and an extended lifespan. These advantages can translate into significant savings on operational and maintenance costs, as new motors are often designed to meet modern efficiency standards and require fewer repairs. Over time, the long-term savings from reduced energy consumption and maintenance can offset the higher initial investment in a replacement motor, making it a worthwhile consideration in the cost comparison process.

On the other hand, repaired motors, especially older models with worn or outdated components, may demand ongoing maintenance to stay functional. Older motors might not operate as efficiently as newer models, leading to higher energy costs and potential downtime for future repairs. For businesses focused on sustained efficiency, the initial savings from repairs must be weighed carefully against potential long-term costs. Factoring in the projected lifespan and efficiency of both repair and replacement options allows companies to make informed decisions that align with their financial and operational goals.

Cost Comparison: Energy Efficiency Considerations in Repairing vs. Replacing Motors

In terms of cost comparison, energy efficiency is a critical factor to consider when deciding whether to repair or replace an electric motor. Newer motors are often designed to meet higher energy efficiency standards than older models, directly impacting operating costs. A new motor consumes less electricity than a repaired, older motor, translating to reduced energy expenses. This efficiency boost not only supports cost savings but also contributes to environmental sustainability, making replacement particularly beneficial in energy-intensive applications. While the initial cost of a new motor is higher, the efficiency gains can help offset these costs over time, providing a strong financial incentive for replacement.

On the other hand, repairing an older motor may restore it to operational status but is unlikely to enhance its energy efficiency. Repaired motors typically operate at the same energy levels as before, meaning companies may still face higher energy expenses with an older, less efficient motor. For organizations where energy savings are a priority, such as those aiming to reduce carbon footprints or lower utility costs, replacement can be a more cost-effective option over the long term. By investing in an energy-efficient motor, businesses can reduce operating costs, improve sustainability, and potentially qualify for energy-related incentives or rebates.

Cost Comparison: Reliability and Performance in Repairing vs. Replacing Motors

In a cost comparison focused on reliability and performance, replacing an electric motor often offers superior benefits for industries where consistent performance is essential. New motors generally deliver higher reliability due to advancements in technology and design, which enhance their durability and operational stability. Unlike older motors that may have accumulated wear, a new motor is built to perform consistently over time, reducing the likelihood of unexpected issues. For industries where even minor disruptions can lead to costly downtime, investing in a replacement motor ensures a dependable performance level that supports productivity and efficiency.

Repairing a motor can restore its functionality, but it doesn’t reverse the wear on critical components that may have accumulated over years of use. A repaired motor is more likely to experience fluctuations in performance or require additional maintenance sooner than a new motor would. For applications demanding high reliability, such as continuous industrial processes, this could mean more frequent interruptions and repair costs. Opting for a replacement in these scenarios minimizes the risk of unexpected breakdowns, ensuring steady performance and reducing long-term costs associated with repeated repairs or production delays.

Cost Comparison: Maintenance Costs and Frequency in Repairing vs. Replacing Motors

In a cost comparison focused on maintenance costs and frequency, new motors often have an advantage over repaired motors. New motors come equipped with updated parts and modern technology, which generally makes them more durable and efficient. Additionally, new motors are often backed by warranties covering maintenance for a certain period, which can help offset future costs. These factors contribute to a lower maintenance frequency, reducing both the time and expense needed to keep the motor in optimal condition. For companies aiming to streamline operations and minimize disruptions, the reduced maintenance requirements of a new motor can translate to significant long-term savings.

In contrast, repaired motors, especially older models, may demand more frequent maintenance to remain operational. These motors may have accumulated wear on components, leading to ongoing issues that require regular attention. While repairing a motor may be initially cost-effective, businesses need to factor in the added costs of maintaining it over time. Increased maintenance frequency can be especially disruptive for industries requiring consistent performance, as more frequent interventions may impact productivity. By evaluating the cumulative costs and downtime associated with maintaining a repaired motor, companies can decide whether replacement might provide a more cost-effective and efficient solution in the long term.

Cost Comparison: Availability of Replacement Parts in Repairing vs. Replacing Motors

In a cost comparison, the availability of replacement parts is a crucial factor when deciding whether to repair or replace an electric motor. Older motors often require components that may be difficult or expensive to source, which increases repair costs and can lead to longer repair times. If these parts are obsolete, it may not be possible to repair the motor without significant expense or delay. As a result, when parts are scarce or priced at a premium, replacement might offer a more practical and cost-effective solution, especially for businesses that cannot afford prolonged downtime or increased repair costs.

For newer motors, replacement parts are generally more accessible and may even be covered by warranty, which can lower repair costs and streamline maintenance processes. The availability of parts for modern models ensures quicker repairs and lower expenses, making the repair option more appealing in many cases. When businesses evaluate repair costs, the ease of obtaining parts for newer motors often makes repair a practical choice. By considering the accessibility and cost of parts in their decision, companies can determine the most efficient and economical approach, weighing the benefits of quick repairs against the long-term investment of motor replacement.

Cost Comparison: Technological Advancements in Repairing vs. Replacing Motors

In a cost comparison focused on technological advancements, replacing an electric motor often provides enhanced functionality, efficiency, and long-term value. New motors come equipped with modern technology, such as variable frequency drives (VFDs) and advanced control options, which boost performance and adaptability. These features allow motors to operate more efficiently, reducing energy consumption and improving ease of use. For companies prioritizing automation or seeking to integrate smarter, more adaptable equipment, a new motor equipped with these advancements offers a compelling return on investment. While replacement costs are higher initially, the benefits of improved technology often translate into greater efficiency and operational flexibility.

Conversely, repaired motors, particularly older models, typically lack these technological upgrades and may not offer the same level of adaptability or efficiency. Without advanced features, older motors can limit a company’s ability to modernize or automate its processes, potentially impacting productivity and competitiveness in the long run. For businesses aiming to future-proof their equipment or streamline operations with automation, investing in a new motor with advanced technology may outweigh the initial cost difference. Factoring in the long-term advantages of modern technology helps companies decide whether a new motor’s capabilities align with their goals for efficiency and innovation.

Cost Comparison: Environmental Impact in Repairing vs. Replacing Motors

When considering environmental impact in the repair-versus-replacement decision, replacing an older motor with a newer, more efficient model often offers long-term sustainability benefits. Newer motors are designed with energy efficiency and eco-friendliness in mind, reducing their overall environmental footprint over their lifespan. For companies aiming to lower their carbon footprint or comply with regulatory standards, investing in a new motor aligns well with environmental goals. In a cost comparison, while replacement involves an initial manufacturing and disposal impact, the reduced energy consumption over time typically balances out this footprint, making it a greener option for many industries.

Repairing an existing motor initially minimizes waste, as it avoids the need to manufacture a new motor. However, older motors generally operate less efficiently, often consuming more energy and emitting higher levels of greenhouse gases. In industries focused on environmental responsibility, the ongoing energy demands of an older motor can outweigh the short-term waste savings from repair. By choosing replacement, companies can invest in environmentally friendly technology that supports their sustainability objectives while meeting operational needs more efficiently. Weighing the environmental impact helps businesses make an informed decision that aligns with both their ecological and operational goals.

Cost Comparison: Warranties and Guarantees in Repairing vs. Replacing Motors

In a cost comparison, warranties and guarantees play a crucial role in the decision between repairing and replacing an electric motor. New motors generally come with warranties that offer financial protection and peace of mind by covering repairs, maintenance, and even replacement parts within a specified period. This coverage can help offset future expenses, making it easier for companies to manage long-term costs associated with motor upkeep. For businesses prioritizing risk management and reliability, a new motor’s warranty provides an added layer of security, allowing operations to continue with minimal financial disruptions.

Repaired motors, however, typically lack such comprehensive warranties, leaving companies responsible for future repairs and maintenance out-of-pocket. Although repairs may initially be less costly, the absence of a warranty means any subsequent issues may require additional expenses, which can add up over time. For businesses seeking dependable equipment with minimal financial risk, the protection offered by a warranty on a new motor can make replacement a more appealing choice. Factoring in warranty benefits ensures that companies choose an option that aligns with both their budgetary needs and long-term reliability expectations.

Cost Comparison: The Value of Expert Evaluation in Repairing vs. Replacing Motors

An expert evaluation can make a significant difference in the repair-versus-replacement decision for electric motors, providing invaluable insights into the most cost-effective path forward. Professionals, like those at A Plus Electric Motor Repair, are equipped to assess critical aspects of a motor’s condition, including wear, performance issues, and estimated remaining lifespan. Through in-depth diagnostics, they can pinpoint specific issues and potential risks, allowing businesses to make informed decisions that reflect the true condition of the motor rather than relying solely on upfront repair or replacement costs. This expert guidance ensures that every option is weighed in terms of long-term value and operational demands.

Partnering with experienced technicians gives companies a clearer understanding of the potential savings and costs associated with each choice. A thorough evaluation can reveal hidden issues or highlight the benefits of modern technology that may make replacement more appealing. Conversely, a well-diagnosed repair may offer sufficient value to extend the motor’s life at a fraction of the cost. By using expert analysis, companies avoid making costly decisions based solely on initial expenses and instead receive tailored advice that aligns with their operational priorities and financial goals. This informed approach supports both efficiency and budget-conscious decision-making in motor maintenance.

Cost Comparison Conclusion: Weighing Repair vs. Replacement for Electric Motors

The choice between repairing or replacing an electric motor depends on a thorough assessment of factors like upfront costs, long-term savings, reliability, energy efficiency, and environmental impact. While repairs typically involve lower initial expenses, replacing a motor can offer substantial operational advantages over time, particularly through improved efficiency, enhanced reliability, and access to modern technology. Evaluating these considerations allows companies to make decisions that align with both immediate and long-term goals, optimizing performance and cost-effectiveness.

Partnering with experts like A Plus Electric Motor Repair can further support this process by providing a detailed cost-benefit analysis tailored to the specific motor and application. With their guidance, companies can make a well-informed choice that balances cost with operational demands, ensuring maximum value from their motor investments. Whether the final decision is repair or replacement, a comprehensive evaluation empowers businesses to achieve optimal results, enhancing equipment longevity, efficiency, and overall productivity.